Realizing extreme miniaturization

The future of product design

has now expanded.

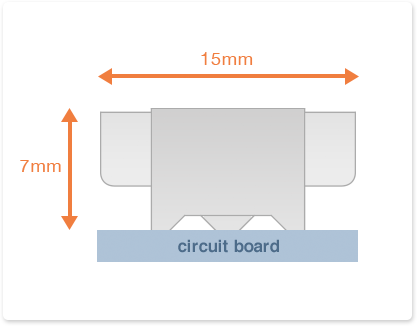

TGS5141 is the latest electrochemical-type Carbon Monoxide (CO) sensor developed by Figaro Engineering Inc. after years of market experience and accumulated technical expertise. With a diameter of 15 mm and a height of only 7 mm*, this ultra-compact, low-profile sensor can fulfill your product development needs.

* Height from circuit board, once installed.

Users can now make

even thinner, smaller products.

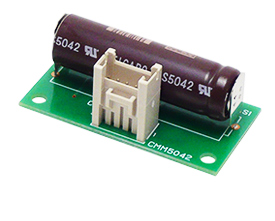

This new CO sensor, developed using a new proprietary electrolyte, does away with the water reservoir of the current model (TGS5042) and requires 1/10th the space once installed, representing significant miniaturization compared to current model. In addition to the obvious implications of size reduction for home CO alarms, usability of TGS5141 in space-limited equipment, such as portable CO detectors and fire alarms, is greatly enhanced.

Compact size with

a long life

Compact size with a long life

In recent years, the demand for combination-type CO alarms and fire alarms equipped with both smoke and CO sensors has continued to rise. With that in mind, Figaro developed a CO sensor with a 10 year life-span to match that of smoke sensors.

The TGS5141 has more than enough catalytic ability to ensure 10 years of operation. And as there is no water reservoir there is no chance of sensor life degradation due to the reservoir drying out.

With 10 year life-span CO sensors, greater safety and peace of mind are within reach.

The miniaturization and profile-reduction of CO alarms and fire alarms saves space.

Reduced product size allows for portable, stylish CO alarms and fire alarms to be produced.

Possibilities for use as yet unimagined.

Due to the advantages of miniaturization and profile-reduction, the combination of CO sensors with technologies such as wireless, voice functions, cameras, air quality sensors, CO2 sensors and night lights is within reach. New levels of safety management are attainable.

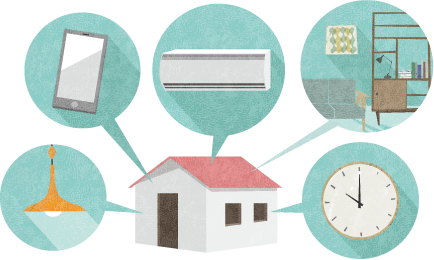

Reduced production time and effort thanks to barcode calibration and wave soldering. *1

As each sensor is fitted with a barcode showing its sensitivity, users can save time calibrating for a particular gas by simply reading the barcode. Wave soldering may be possible which could greatly reduce production costs.

*1 Since soldering conditions vary greatly, tests should be conducted to assure that sensor performance is not adversely affected.

Made in Japan.

Ideal for mass roduction.

All the sensors are made in Japan. Every product is tested with CO gas to ensure quality you can trust. And thanks to our automated production line, we can handle large or urgent orders.

TGS5141 conforms to the following international technical standards.

*2 TGS5141 is a UL recognized component and is therefore exempt from the 1 year long-term stability test for UL2034.

*3 For compliance with EN50291, gas calibration is recommended instead of calibration via barcode scanning.

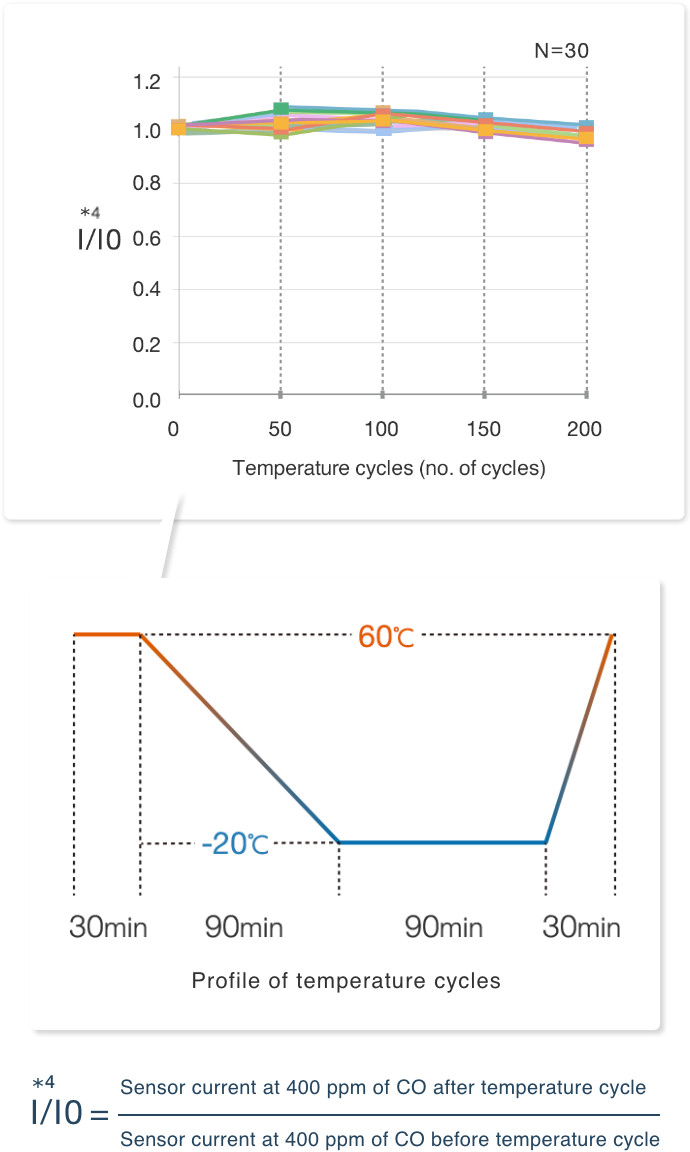

Functions despite sudden, large changes in temperature and humidity.

Enables a wide range of usages in a variety of situations.

Current CO sensors can enable fire detectors to meet the European standard fire detectors. However, some environments into which fire alarms are actually installed are much harsher than the environmental conditions considered by the standard. As a result, usage of CO sensors in fire detectors has been limited to less severe environmental conditions.

The TGS5141 uses a solid electrolyte which is not significantly influenced by changes in humidity, so when compared to current electrochemical CO sensors using sulfuric acid or water reservoirs, it has considerably greater durability to sudden and large temperature/humidity changes, making it more suitable for fire alarms.

The potential for highly functional fire alarms equipped with CO sensors is increasing.