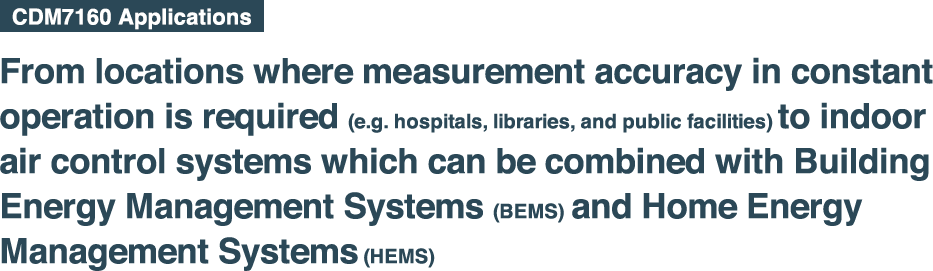

CDM7160/World leader in gas sensing innovation

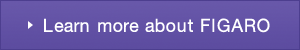

Measurement of gas concentration by measuring the absorption ratio using two detector elements

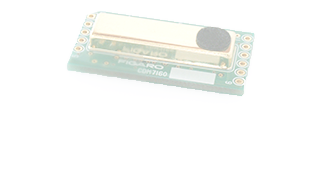

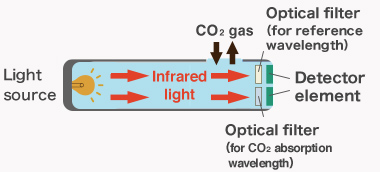

CO2 sensors employing a single detector element typically utilize gas concentration correction software with the assumption that CO2 concentration in unoccupied space is around 400ppm. However, in an environment where many occupants are present at all times, or when CO2 gas concentration remains in excess of 400ppm, ambient CO2 concentration never falls to 400ppm, resulting in less accurate measurements due to inappropriate software corrections. The CDM7160 employs two detectors with different optical filters in front of each detector. One detector measures the intensity of transmitted infrared light of the wavelength region that is absorbed by CO2 gas (i.e. the CO2 absorption wavelength). The other detector measures the intensity of transmitted infrared light of the wavelength region that is not absorbed by CO2 (reference wavelength) and unaffected by CO2 concentrations, enabling effective correction of CO2 measurements.

Measurement principle of dual wavelength

system

Measuring infrared light intensities in two wavelength bands passing through each of the optical filters

CDM7160 measures infrared light intensity at the reference wavelength simultaneously, and calculates CO2 concentrations from the difference between light intensities at the CO2 absorption wavelength and the reference wavelength, resulting in accurate and stable measurement of CO2 gas concentrations.

- Source of figure:

- ・NIST Chemistry WebBook

- ・NIST Standard Reference Database Number 69

- ( NIST: National Institute of Standards and Technology, U.S.Department of Commerce )

Reliable single light source, dual wavelength sensor

NDIR CO2 sensors are generally classified into three types:

- Single light source, single wavelength system

- Dual light source, dual wavelength system

- Single light source, dual wavelength system

The CDM7160 employs a single light source, dual wavelength system using two optical filters and measures intensities of the infrared lights at two different wavelength bands passing through each of the optical filters respectively, resulting in accurate measurement of CO2 gas concentrations. Furthermore, stable sensor output throughout a long period of operation is achieved by proprietary signal processing technology.

| System | Single light source, single wavelength sensor | Single light source, dual wavelength sensor |

|---|---|---|

| Design | Measures a single wavelength from a single light source | Measures two wavelengths split from a single light source |

| Structure |  |

|

| Feature Comparison |

Accuracy decreases when used in places where CO2 concentration remains high due to continued presence of occupants, such as small retail stores or hospitals.

|

High accuracy is maintained by comparing IR intensities of two different wavelength bands even when used in applications where people are continually present, such as small retail stores or hospitals.

|

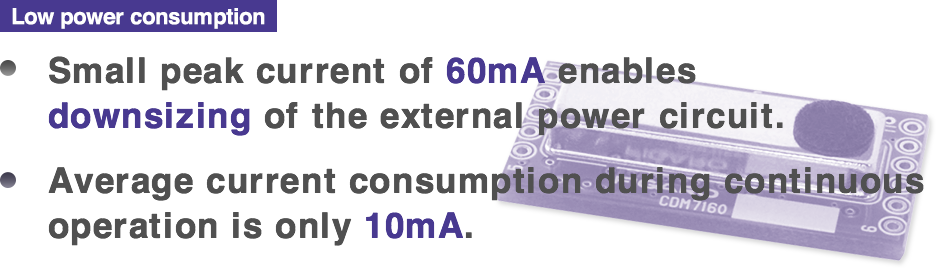

Compact size with thickness of only 7.5 mm fits in well with low-profile environmental monitors or controllers.

Customer and Technical Support

Based on the in-depth knowledge and expertise that Figaro has acquired through its 45+ years of experience in supplying high quality gas sensing solutions to global markets, Figaro provides sound and responsive technical support for application circuit design, selection of electronic components, detector housing design, gas detector manufacturing process, and other customer-specific technical questions.

Content-rich Technical Documents

Individual product data sheets, detailed technical information and application notes are available for customer’s reference.

Suitable for a wide range of applications such as ventilation control equipment, air conditioning equipment, and small measuring devices for indoor environmental comfort and energy efficiency. Expected application includes input devices for environmental measurement in IoT and M2M products.

Made in Japan.

All CO2 sensors are factory calibrated to standard CO2 gas in a computer-controlled automatic calibration system. Stringent quality control processes at Figaro ensure high reliability of its gas sensors.

Figaro has a wide range of product lines, including semiconductor VOC sensors for detection of low concentrations and battery operable electrochemical CO sensors. Figaro is one of the few gas sensor manufacturers in the world supplying VOC, CO, and CO2 gas sensors.

| VOC | CO | CO2 |

|---|---|---|

| MOS type | Electrochemical type | NDIR type |

|

Click the model number for more details.  ・TGS2600 ・TGS8100 |

Click the model number for more details.  ・TGS5141 |

Click the model number for more details.  |