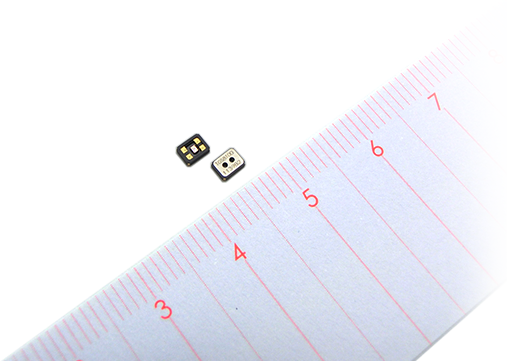

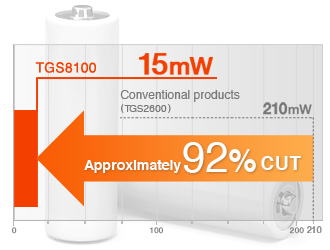

Smaller, with significantly reduced power consumption. The history of gas sensor development has frequently focused on miniaturization and reduced power consumption. Figaro Engineering has succeeded in development of the TGS8100 MEMS semiconductor gas sensor, boasting a size and power consumption among the lowest in the world which in turn simplify product design and enhance automated manufacturing.