Over its long history, Figaro Engineering has continually expanded its development and production activities in the specialized field of gas sensors. Some of its product lines have a 20+ year track record of dependability, durability and safety.

To ensure that it remains ahead of the needs of its customer and of society in general, Figaro will continue its technical innovation by expanding the functionality and productivity of its product lines in order to enhance convenience and safety.

About FIGARO/World leader in gas sensing innovation

Within the massive world-wide market for electronic products, Figaro Engineering boasts the top sales volume for gas sensors.

The specialized nature of the gas sensor market allows Figaro to focus on gas sensing issues and conduct in-depth research. Figaro intends to continue moving forward with this approach.

Gas Sensors by Figaro

Figaro offers a wide range of gas sensor products for the detection of various gases, from explosive gases such as propane, toxic gases such as carbon monoxide, to air quality sensors for volatile organic compounds (VOCs) that are responsible for sick-house syndrome. Figaro offers a diverse portfolio of sensor technologies that can be matched to the unique requirements of each application.

All electronic products are subject to persistent demands for miniaturization and reduced power consumption. Gas sensors are no exception. To respond to these requirements, sensor Research and Development continues in an effort to discover hidden possibilities.

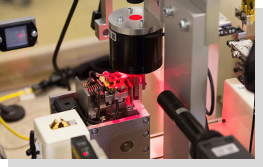

The latest result of such Research and Development work is MEMS sensor element products. Characterized by their extremely small size, these products boast power consumption of less than one-tenth of conventional products, opening up new possibilities for portability and mobility of products using these sensors.

“Figaro Engineering has become a brand whose gas sensor shipments rank among the highest world-wide. However, when I joined the company, it was a venture business in the form of a Research and Development organization. Although this organization has grown into a mid-sized company, it has nevertheless maintained its original culture of specializing in product development as the focus of each and every employee. This company culture is a primary reason for the high level of praise Figaro receives from the industry.”

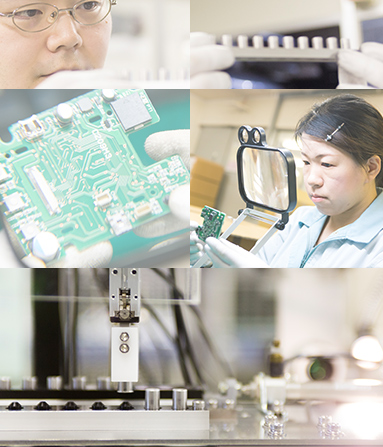

The true value of a parts manufacturer lies in its ability to manufacture parts of consistent quality in large quantities. The same applies in the world of gas sensors.

Figaro Engineering's in-house development of automated production equipment incorporates advanced production technology such as thick-film printing that enables manufacture of uniform, high-quality gas sensors in large quantities. The company’s huge production capacity is far ahead of its competitors and permits a flexible response to customer requirements.

A global supply system for the world market

To respond to differing needs by country, Figaro has established a world-wide network that includes a branch in the United States and distributors in Europe and Asia. This ensures that products satisfying the unique needs of each customer can be supplied on a timely basis and in the appropriate volumes, further promoting the company’s growth.

The high quality of Figaro gas sensors can be attributed to the company’s world-class manufacturing and supply system. The manufacturing process in which this quality is maintained is precisely managed.

Written procedures ensure that uniform product quality is maintained. Furthermore, by continually monitoring product quality, engineers are able to detect minute changes that occur in processes, thus ensuring that high quality gas sensors are manufactured.

All products are naturally inspected for electrical quality, with engineers focused on zero-defect manufacture. The benefits of this monitoring are apparent in the market’s evaluation of the quality of Figaro products.

Constant reporting of variances

to monitor changes

Figaro’s entire staff of manufacturing and quality management holds daily variance report meetings to ensure that no mistakes are overlooked. To ensure certainty and consistency in manufacturing, reports are shared on anything that varies from the norm at manufacturing and quality management sites.

A sales engineering system focused on customer orientation, covering the entire process from gas sensor development to installation

Each and every one of Figaro's sales engineering personnel is responsible for all aspects of sales activity, from customer contact and offering development advice to product introduction and follow-up services.

Sales engineers frequently have experience in the Development division and are able to give technical advice on current products and to gather technical information on future development, all in order to satisfy a customer’s unique needs.

Information on customer needs is gathered by sales engineering personnel and investigated primarily by the Development division, who in turn hold brainstorming sessions with the Manufacturing and Management divisions to provide customer advice. Sales personnel have links across all divisions, creating a sales and development system based on customer requirements.

A training system to support sales engineering and to develop human resources

Figaro Engineering employs large numbers of personnel from various scientific fields and assigns them to various divisions within the company, including R&D, to build experience and develop the basic knowledge and skills required of engineers. Those engaged in sales are referred to as ‘Sales Engineering’ personnel since they have experience in development and are well-grounded in technical matters, with the wide experience appropriate for responding to customer needs.